CEMENTING THE BILGES

The engine room has been cleaned out. The steelwork has been sandblasted and coated with zinc-rich primer. The wood work has been scraped back and blasted, it is ready for the cement to be put back in.

The bilges have always been cemented to make the water run off without collecting anywhere. We have researched the technique and it was common when Glala was built. It is very important that there is no trace of paint or other muck on the wood if the tar is to bond and be fully preservative. We had the timber lightly sand blasted, the timber is deeply stained by the old tar but it is clean.

Once the timber is bare the first stage is to coat it with hot tar.

The process continues into the after section. Cement is laid over the tar. Finally it is painted grey.

DECK BEAMS

The first deck beams are going in, they are laminated Douglas Fir which has a good strength to weight ratio. The beams are let deep into the cabin sides which are braced with a beam shelf.

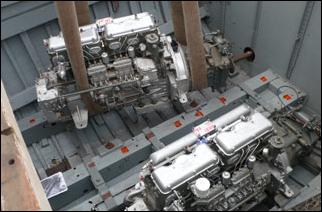

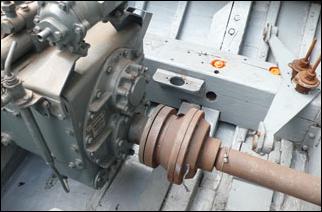

ENGINES

Return of the engines. It's just a trial fit at this stage, they will be measured for new, much bigger, mountings.

|